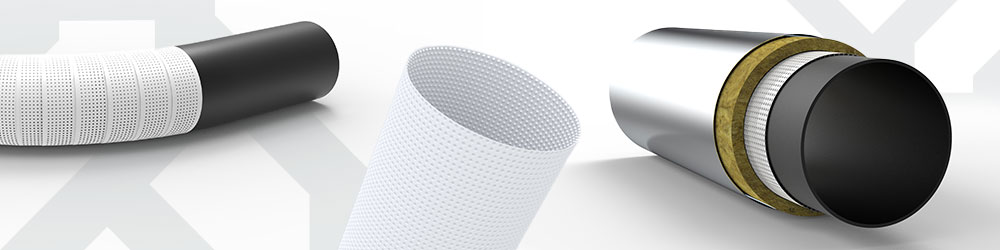

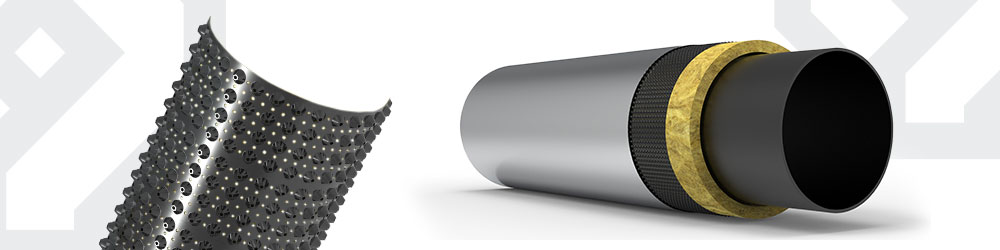

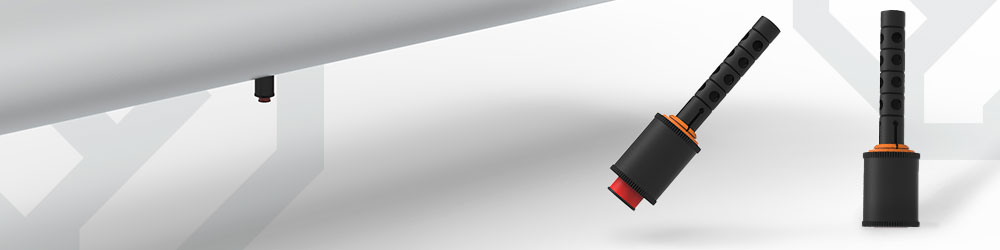

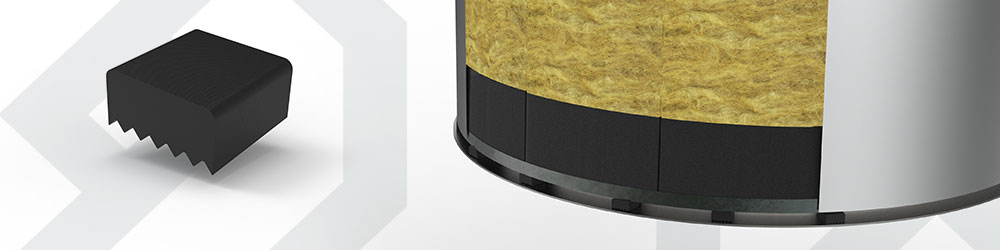

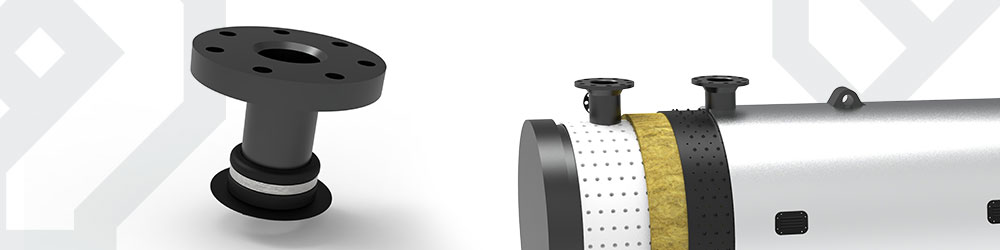

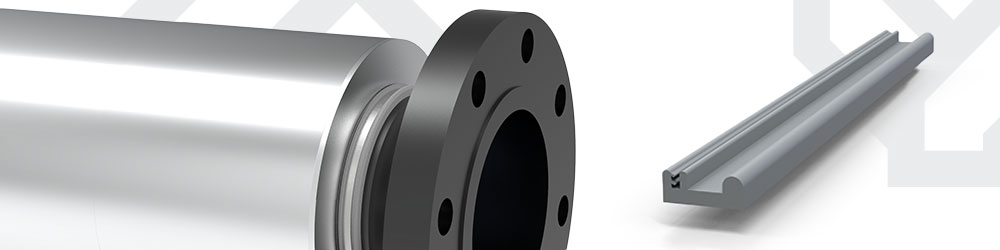

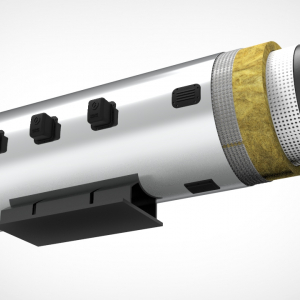

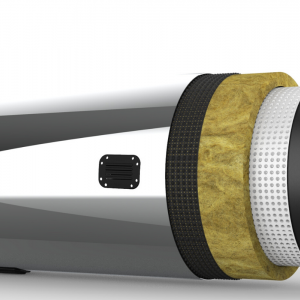

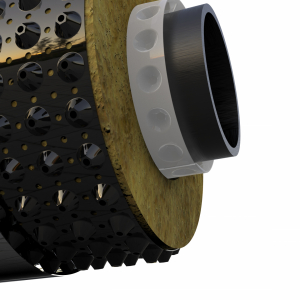

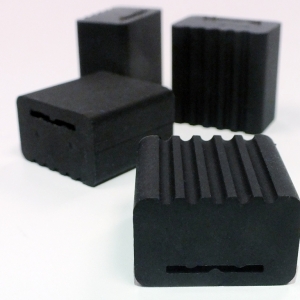

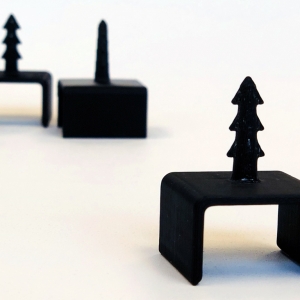

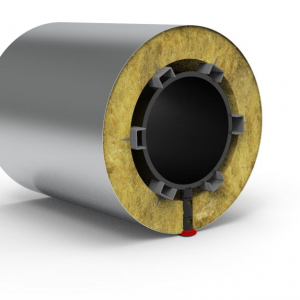

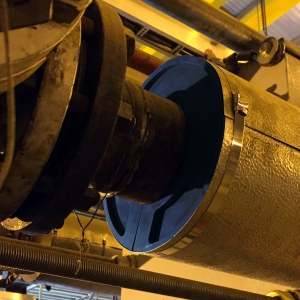

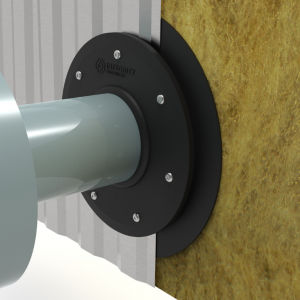

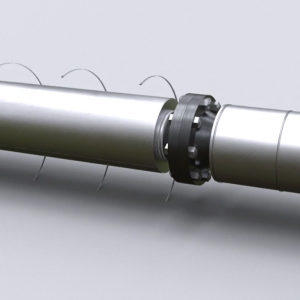

Corrosion Under Insulation (CUI) Products

Corrosion Under Insulation (CUI) can no longer be considered an ‘out of sight, out of mind’ issue. Aging infrastructure has brought CUI to the forefront, with costs surrounding CUI-related problems estimated to be in the billions of dollars each year. However, this number can be greatly reduced by implementing systems which allow for early detection, access for inspection, ongoing monitoring, moisture mitigation, and safeguards to isolate problem areas. While there is no way to prevent CUI mitigation fully, monitoring strategies can greatly reduce the incidence and costs (human, capital, social, and environmental) related to CUI and Stress Cracking Corrosion (SCC) on thermally insulated assets.

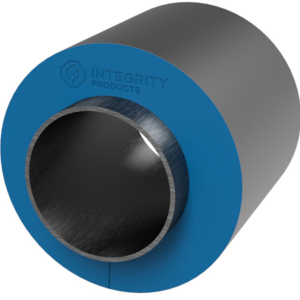

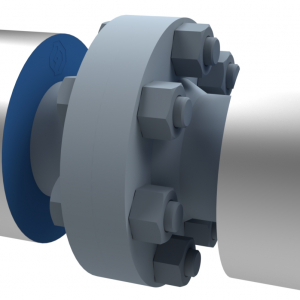

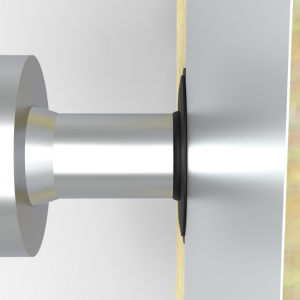

At Integrity Products & Supplies, we pride ourselves on being CUI Specialists™. Our in-house Research & Development (R&D) team, combined with global procurement, allows us to provide innovative and cost-effective solutions to CUI problems. We have commenced R&D projects, and our technical findings made their way to peer-reviewed publications. With our findings, our products align with the most recent industry standards ASTM G189-07, API 583, and NACE SP 0198. Our Corrosion Under Insulation products is designed to work together as part of a holistic CUI monitoring and mitigation system or on their own, depending on the needs of each specific application.

Our product line is constantly evolving, so contact us directly for the most up-to-date solutions to fit your needs.